Have any questions?

+44 1234 567 890

emkon. packaging machinery: robot solutions

Articulated robots – the decathlete among the gripper arms

Articulated robots in packaging machine engineering

Articulated robots are industrial robots with a serial arrangement of axles. They are equipped with three rotary main-axles, which enables movements three-dimensionally. Usually they are used as 5- or 6-axle articulated robots. Its greatest benefit: the enormous flexibility and mobility in comparison to gantry robots. Thus, they are able to manage complexly technical tasks.

“We use the articulated robots for pick & place-applications and for heavy loading jobs (e. g. palletizing)”, says Jens Hilger, Sales Manager Food/Non-Food at emkon. Several arm links are connected by six axles and can make movements in almost every direction.

Gallery (5 photos)

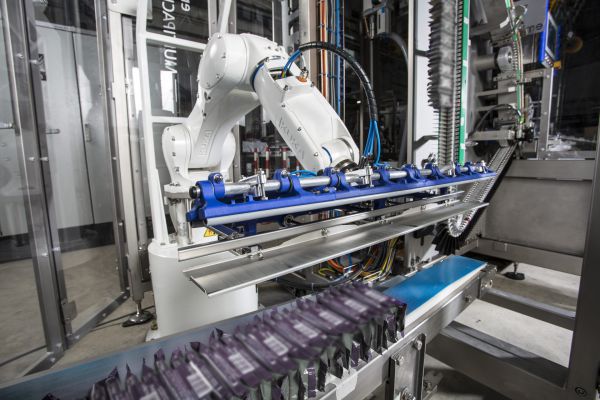

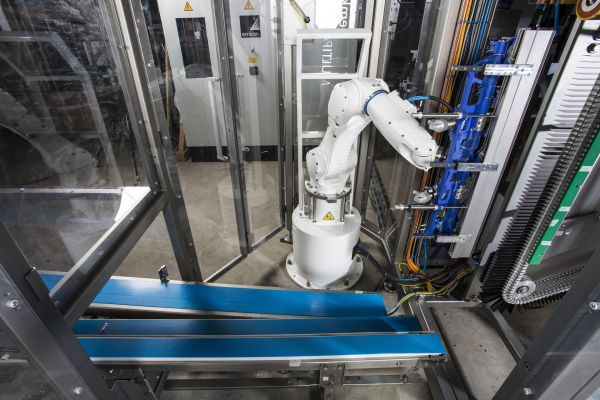

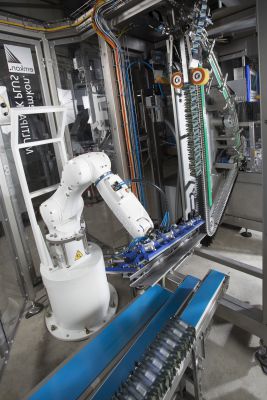

New machine with articulated robots

In one of our last projects, we have used the articulated robot in collaboration with our machine emkon. MULTIPACK. In this project, the robot grabs a filled magazine with chocolate bars from a vertical pocket chain and turns it 180 degrees. Afterwards the robot puts the products in horizontal position onto a conveyor belt (one of three) which leads to the subsequent process.

The picking and placing by robot application in our new emkon. MULTIPACK PLUS is much faster than the conventionally turning and placing methods. Additionally, the mechanical strain and due to that the later spare parts requirement is considerably reduced. “In this case, we developed particular gripper tools to meet customer demands. The gripper tools were manufactured in 3D-print and fixed on the robot arm”, says Hilger.

Articulated robots at a glance

- Large motion range

- High mobility level

- Weight load of approx. 1000 kg possible